ATO high torque stepper motors are particularly advantageous in CNC machinery and 3D printing environments, where forceful and accurate movement is essential. These motors are engineered to deliver high holding torque without sacrificing resolution or step accuracy, allowing for strong, consistent motion even under heavy load conditions. In CNC routers, mills, and laser cutters, high torque stepper motors like the NEMA 23 and NEMA 34 ensure spindle heads or cutting tools follow precise paths, contributing to exceptional detail and product finish. Their ability to maintain torque at low speeds without feedback mechanisms reduces system complexity and enhances mechanical stability.

In 3D printers, especially larger models, the torque-to-inertia ratio of these motors helps manage the inertia of moving platforms or extruder assemblies. Smooth layer deposition and accurate filament positioning depend heavily on the motor's ability to resist mechanical backlash and vibration. When paired with microstepping drives, ATO high torque stepper motors can achieve resolutions finer than 0.01 mm per step, which is critical for producing high-definition prototypes or engineering-grade parts.

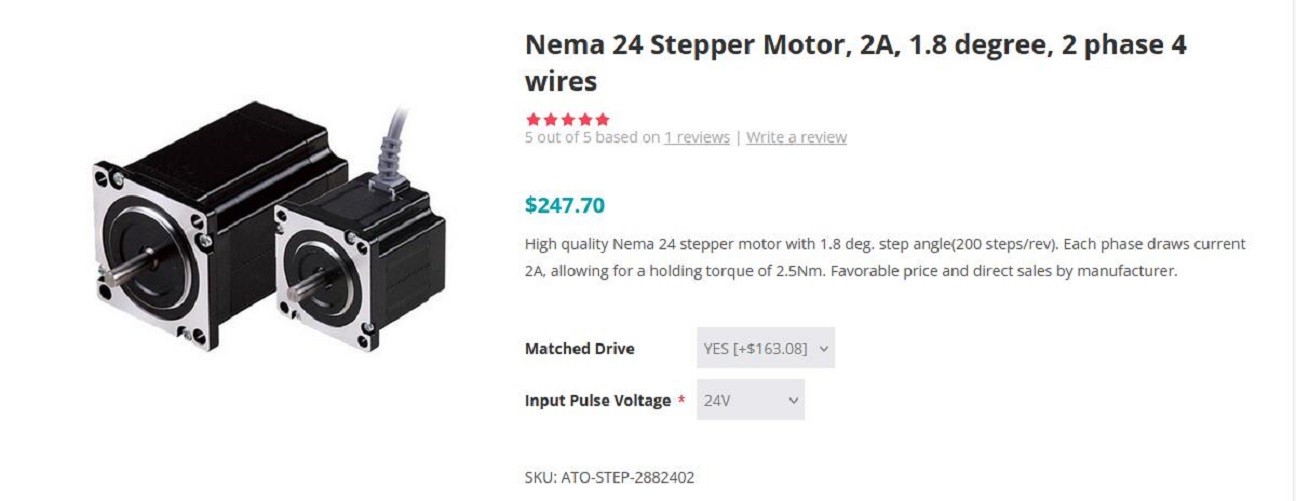

Their compatibility with various supply voltages such as 5V, 12V and 24V extends their utility in both hobbyist and industrial applications. For instance, a 12V high torque stepper can be used in desktop 3D printers or compact milling machines, while a 24V variant is more suitable for demanding automation setups. With heat-resistant windings and low detent torque, these motors maintain performance over extended operating cycles without overheating or losing position.

ATO also supports custom mounting options and shaft configurations, allowing seamless integration into retrofitted or proprietary systems. By providing high torque in a compact form factor, these stepper motors empower engineers and makers to build more capable machines within tight space and budget constraints. Whether for cutting metal, printing polymers, or carving wood, ATO high torque stepper motors ensure consistent, powerful, and accurate movement — making them a staple component in modern precision machinery.