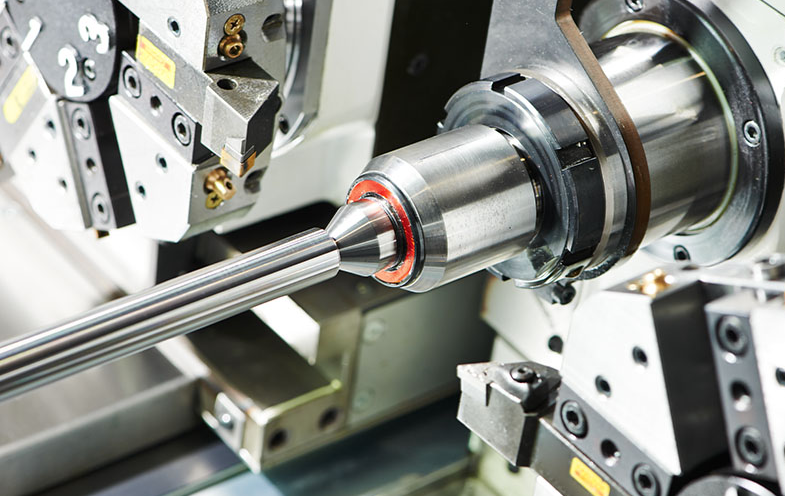

It is important to be aware of the most common issues that can arise while using a tabletop CNC mill for normal operations. CNC machine failures are discussed here.

After the machine tool is powered up, the CRT has no gray scale and no picture. Other sections of the machine tool appear to be functioning normally, and the electric control cabinet contains no anomalies.

Check the CRT's cable connection and the adapter plug in the electric control cabinet to make sure there are no loose or disconnected connections. Check the CRT's input voltage. CRT power supplies come in a wide variety of types and voltages depending on the manufacturer. As a general rule, 9in monochrome CRTs are often powered by +24V DC, while 14in color CRTs are typically powered by 200V AC. As a result, you must first gather all of the relevant information about the equipment and its current state. The device accepts DC 24V as an input voltage. There is a list of the most frequently encountered CNC machine tool problems.

The actual failure of the CRT unit. Display, regulator, and other components make up the CRT unit. A simple, intuitive approach is all that's required for this type of inspection. Our computer's display is also devoid of any video signal after connecting the MMC circuit board in the NC system to the PC. Consequently, we can deduce that the issue is with the MMC board, which should be handled with care when dealing with a circuit board problem. It is easy to lose data when there is an issue with the circuit board in a numerical control system. An MMC board, in particular, is like a stand-alone computer, complete with its own hard drive and RAM. In the event of a malfunction, we first make a full backup of the device and ensure that one end of the cable is disconnected before connecting it. When disassembling the VCE series CNC single column vertical turning center of cable connector, it is imperative that the circuit board be in a power failure state so that no data is lost or the cable connector is burned due to a small fluctuation. After determining the problem, simply apply the correct medicine to the situation and the issue will be resolved.

a list of the most common CNC machine failures

a. Feeding the driving system

There are two types of feed drive systems: direct current (DC) and alternating current (AC). Three types of failures can be identified. Alarm information can be displayed on a CRT using a diagnostic software program, or it can be displayed using hardware on the speed control unit (LED indication, fuse fusing, etc.). There is no problem with any alarm indication, as can be seen in the first two examples.

2. An alarm notification in the form of software

The system monitors and alarms the feed drive to display this type of alert on the CRT. Error alarms of the servo feed system are the most common cause of these alarms, which are usually caused by faulty speed control or failures in parts related to position control or servo signal of NC. The second most common cause is a fault in the relevant detection elements (speed measuring motor, resolver or pulse encoder). The third most common cause is an alarm about overheating, such as the servo unit, transformer, and motor.

The third type of alarm is a hardware alarm.

On the speed control unit, this includes an alarm indicator light and fuse fusing, as well as the tripping of numerous safety switches. The alarm indicator's significance changes based on the speed control device it's attached to. In general, the following scenarios occur:

A single high-voltage alarm. AC power supply voltage or motor insulation capacity exceeding ten percent of rated value are the two most common causes of this type of warning. The insulating capacity of a motor can be measured using a megger.

2 Overheating alarms. A faulty thyristor or transistor module in the speed control unit is the most common cause of this warning. In the event of a power outage, check the module's collector-to-emitter resistance with a multimeter. Having a reading of less than 10 ohms indicates that the module is damaged.

3 Alarm for low voltage.

In the event of an overload, four alarms will go off. Due to the extended service life of this equipment, there are many mechanical loads that have been severely worn, and the top limit of motor current on the speed control unit has been set too low. It is possible to modify the current's setting value.

Alarm with five-speed feedback. The most common source of this type of warning is a servo motor with a bad speed or position feedback line or a bad connector contact. Another possibility is the NC's feedback signal processing module.

6 Either the fuse blows or the circuit breaker malfunctions. This type of alert might have a variety of causes, each of which must be considered in light of the particular circumstances. If the alarm continues to go off after the fuse has been replaced, it is necessary to track down the root cause.

Switching to 7 protection mode. The cause for this type of warning is likewise fairly easy if it is an obvious protection switch activity. Repeat the action, such as a travel switch, to avoid it. Finding out what's causing an overheated transformer and a tripped air switch is critical. Both the set value problem and overheating in the processing process contribute to these issues.

⑧ Failure with no indication of an alarm. Machine tool vibration, machine tool out of control, excessive machine tool noise, etc. are all examples of these problems. Such situations necessitate careful study and a decision based on the facts of the case at hand.